In the world of 3D printing, Polylactic Acid(PLA) has emerged as a star material,favored by both professionals and hobbyistsalike. lts widespread adoption can beattributed to a myriad of advantages thatcater to diverse needs and preferencesHere's a closer look at why 3D printers oftenrecommend PLA as their go-to material:

1. Ease of Use

At the forefront of PLA's appeal lies its user-friendliness. As a biodegradable plastic, PLAboasts a relatively low melting point,making it incredibly easy to handle andprocess. This characteristic not onlysimplifies the printing process but alsoreduces the risk of damaging the 3Dprinter's hardware due to overheatingNovices can confidently experiment withPLA without worrying about intricatetemperature settings or complex post-cessina steps。

2.Cost-Effective

Cost is a crucial factor influencing materialselection, especially for beginners andhobbyists. Compared to other materials likeABS (Acrylonitrile Butadiene Styrene) orPETG (Polyethylene Terephthalate Glycol),PLA filaments are generally more affordable.This affordability allows enthusiasts toexplore their creativity without breaking thebank, making PLA an ideal starting point foranyone venturing into the world of 3Dprinting.

3. Low Warping

One of the challenges faced by 3D printingenthusiasts is warping, a phenomenonwhere the printed object distorts during thecooling process. Fortunately, PLA excels inthis regard due to its low shrinkage rates.This characteristic minimizes warping anddeformations, ensuring that the finalproduct closely resembles the digitaldesign. As a result, PLA is the preferredchoice for creating intricate and detailedmodels.

4. Safety

Health and safety are paramount concernsin any workspace, and PLA delivers on bothcounts. During the printing process, PLAemits fewer toxic fumes than somealternative materials. This makes it safer forindoor use, reducing the risk of adversehealth effects on users and minimizing theneed for ventilation systems. For those whoprefer to work in enclosed spaces or havelimited access to well-ventilated areas, PLAoffers a reassuring level of protection.

5. Widely Available

Another advantage of PLA is its widespreadavailability. Manufacturers offer PLAfilaments in a vast array of colors andfinishes, catering to every user's uniqueaesthetic preferences. This diversity not onlyenhances creative freedom but also ensuresthat there's always a suitable PLA option forany project, no matter how specific therequirements may be.

6.Environmentally Friendly

In today's eco-conscious world, PLA'sbiodegradable nature sets it apart. Unliketraditional plastics that take centuries todecompose, PLA can break down intonatural components under specificconditions, significantly reducing waste andaligning with sustainable practices. Forindividuals and organizations committed toreducing their carbon footprint, PLA offers aguilt-free printing experience.

7. Good Surface Finish

Finally, PLA's ability to produce smoothsurfaces and sharp details makes it suitablefor a wide range of applications. Fromprototyping to decorative pieces, PLA'saesthetic qualities ensure that the finaproduct looks polished and professionalThis characteristic, combined with its otheradvantages, makes PLA a versatile andreliable material for 3D printing enthusiastsof all skill levels.

How to set the printing parameters for PLA?

The most basic setting for different consumables is the printing temperature and hot bed temperature. The parameters are not fixed and need to be adjusted according to the actual situation. For example, consumables that have been stored for a long time need to increase the printing temperature, and special PLA also needs to increase the printing temperature. We need to note that the printing temperature should not be blindly increased. When the temperature is above 220 ° C, it is easy to cause bubbles inside the PLA, resulting in poor printing effect. If the hot bed temperature is too high, it will cause the bottom of the model to melt.

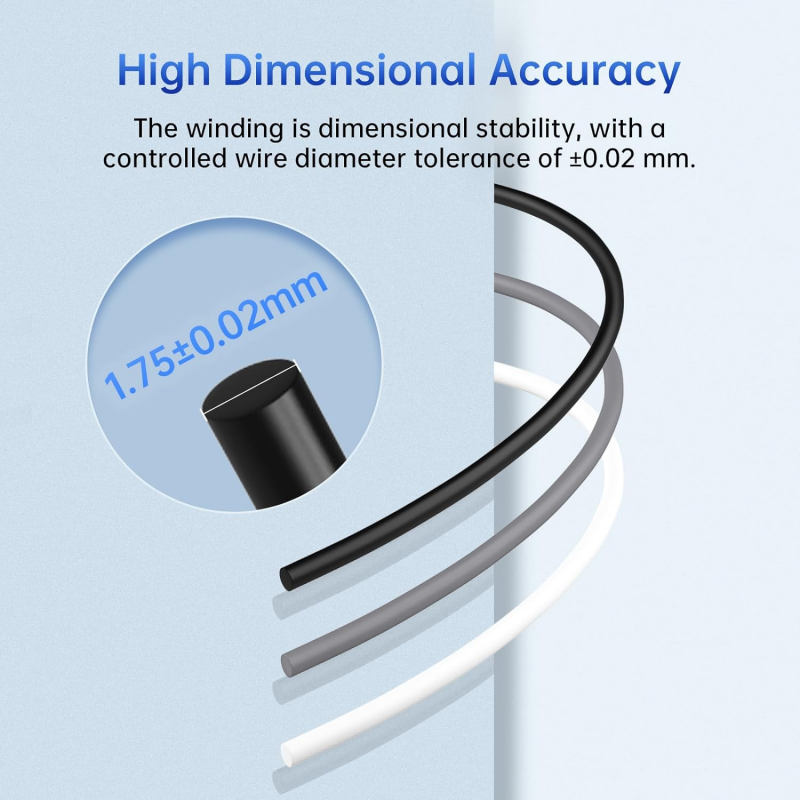

How can we select high-quality PLA?

① The material purity should be high

② The thickness of the wire is consistent, and the cross-section is close to a circle.

We need to observe whether it has color differences, spots, and small bubbles. If the above phenomena exist, it indicates that it contains a lot of recycled materials.

Next, take out a wire about 1 meter long, use a measuring caliper or brush it with your hand to check if the thickness is consistent and the surface is smooth. Then use a caliper to clamp the line and rotate it for one circle. If the rotation is smooth and there are no scratches on the surface, it indicates that the cross-section of the consumable is relatively round.

When printing, observe the printing effect of the first layer (with the printing platform leveled), mainly focusing on its width and uniformity. The extruded wire is relatively uniform and flat, indicating that it has fewer impurities and high quality.